How to perform measurements

Please watch our tutorial videos for PlasTell and FabriTell:

Step 1 - Turn the machine on

Simply plug in the machine into power using the supplied USB adapter. Please don't use any other USB adapter than the one supplied with the machine - it might not provide sufficiently high quality power! (To turn the machine off when you are done, simply unplug it.)

There is no power button - the machine will start automatically.

Step 2 - Self-calibration

The machine will show "CALIBRATING, PLEASE WAIT" - you must not place any items / samples on the sensor while this is happening! When it's done (it takes about 10 seconds), the machine will display "READY".

Step 3 - Measure!

Simply put the item on the sensor and the machine will show the results in less than a second!

Step 4 - Obtaining accurate results

Rule 1 - Do not move the sample

Please ensure that you do not move the sample while the machine is measuring. The machine tries to detect if you accidentally move the sample while measuring (it would show the KEEP STEADY error message). See the images above for the best way to measure - put item quickly onto the sensor then wait.

Rule 2 - As flat as possible

Place the item on the sensor as flat as possible and as stable as possible.

Rule 3 - Push down soft items

Especially with our FabriTell device, it is important you push the sample onto the sensor so that it forms a flat and continuous layer.

Rule 4 - Black and dark samples

Most black and dark plastics can't be identified. This is because the manufacturers add a pigment, carbon black, which absorbs all the infrared rays and as a result, we don't observe any useful signals. This is a problem for our machine as well as for any other near-infrared machine - if you need to identify black samples you need other techniques such as FTIR or XRF. The good news is that dyes are being developed which are black yet don't prevent the identification and multiple plastic container manufacturers have now started using them so we expect this situation to improve in the future.

Most black and dark fabrics can be identified. For natural fibres (e.g. cotton and wool), black dyes are used and not pigments and there are typically no issues. For synthetic fibres (such as polyester, polyamide and acrylic) the manufacturers either use dyes (which coat the surface of the fibres) which cause no issues or pigments (which are added to mixture before spinning the fibres, such as carbon black) which do cause problems.

The machine includes a detection system for dark and black samples - the screen will show "TOO DARK".

Rule 5 - Orient small samples

When measuring with smaller samples , completely covering the detector is best. The sample should be placed in the middle, the same as the photo on the right.

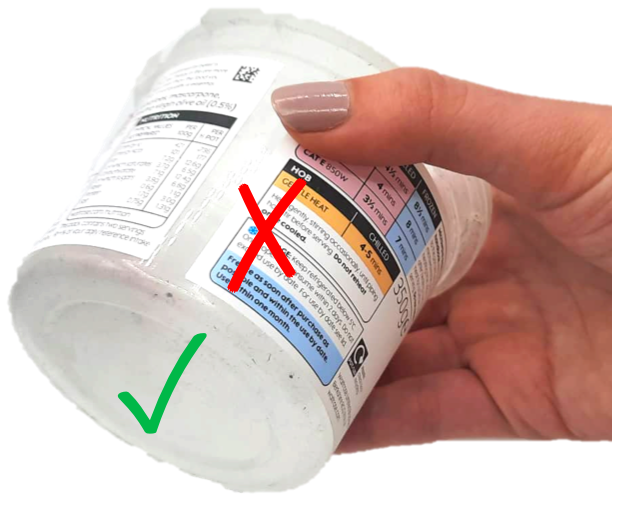

Rule 6 - Don't cover transparent samples (PlasTell)

If the plastic sample is transparent, you must not cover it with your hand - you would prevent the external lamp of the device from shining through the sample.

Rule 7 - Don't measure printed areas or labels

Labels and printed areas of both plastics and fabrics are often made of different material than the rest of the item. You must not measure such areas as the identification will not be accurate.

Rule 8 - Fold thin samples

Usually, the thicker a sample is, the better results can be obtained. You should fold thin plastic films and all fabrics .

Rule 9 - No moisture or water

Any water content or moisture content in fabrics or plastic containers will affect the measurement. Please ensure the item is dry!

Rule 10 - Thick transparent plastics

For very thick transparent polymers, we recommend measuring across a thinner section for best results - see below.