1. Avoid blends.

Mixing materials makes recycling and identification a lot harder. Whilst our FabriTell devices do a good job at identifying blends, it is always easier to identify AND recycling pure materials. Pure materials are also more valuable than blends which helps to make the sorting & recycling financially viable.

2. Don't mix more than 2 materials

If you have to use blends, definitely don't mix more than 2 materials. The more materials you mix, the harder it becomes to actually identify them and sort them.

3. Make garments uniform

Infrared identification machines such as ours can only see the surface of the garment. Making the inside different (such as the black polyester lining on otherwise blue viscose jacket) could result in incorrect identification.

With our machines, you can always scan the inside and the outside of the garment separately but it certainly would be easier if the garment was uniform.

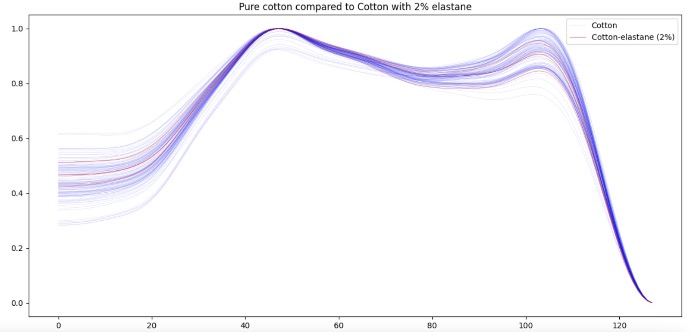

4. Avoid components with < 5%

The spectra of pure materials vs materials with trace contamination (such as 2% elastane in the graph on the left) look virtually the same.

Our state of the art algorithms can typically detect 5% but this is already very challenging.

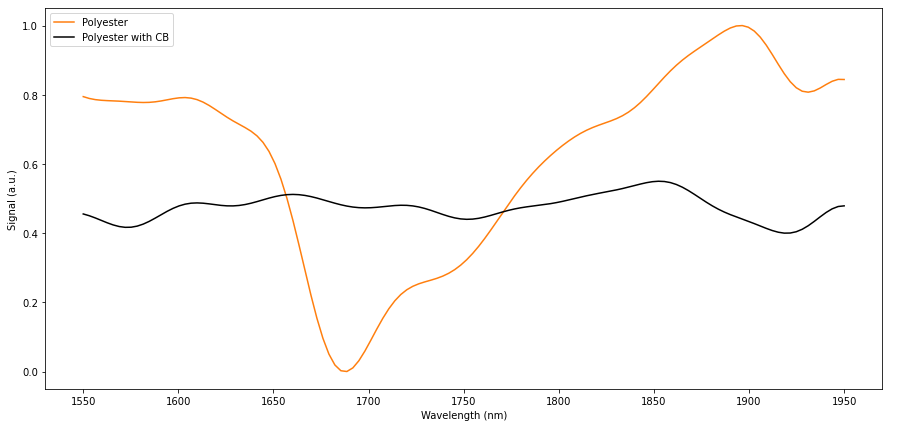

5. Avoid carbon black

Carbon black, a cheap black pigment, absorbs all NIR light and as a result, no useful information come back to the device - just noise. Most black pigments and dyes are actually sortable so it should be straightforward to avoid it.

(Image on the right - spectra of a polyester sample (orange) and a polyester sample with carbon black pigment (black), showing how the CB pigment prevented material identification)

Any questions?

If you have any questions please do get in touch! We would be also happy to check any textile samples you might have to see how sortable they are!